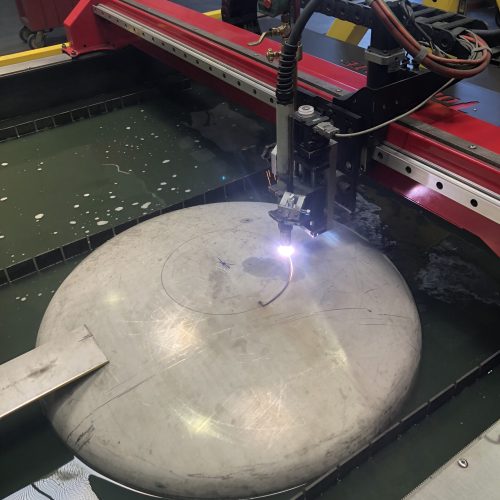

Plasma cutting is a versatile and efficient metal cutting process that uses a high-velocity jet of ionized gas to melt and remove material, producing clean and precise cuts in a variety of metals, including steel, aluminum, and stainless steel. It is widely used in industries such as fabrication, automotive, and construction for its speed, accuracy, and ability to cut through thick materials.

Plasma cutting is a highly effective metal cutting process that utilizes a concentrated jet of ionized gas, or plasma, to melt and sever through various metals with remarkable precision and speed. By generating temperatures of up to 30,000 degrees Fahrenheit, plasma cutting can swiftly slice through materials ranging from thin sheet metal to thick plates, producing clean and precise cuts with minimal heat-affected zones. This versatile method finds extensive application in industries such as manufacturing, construction, and automotive, where it is employed for tasks such as fabricating intricate parts, shaping components, and cutting through heavy-duty materials. With its ability to handle a wide range of metals and thicknesses while delivering swift and accurate results, plasma cutting stands as a cornerstone technology in modern metalworking and fabrication processes.