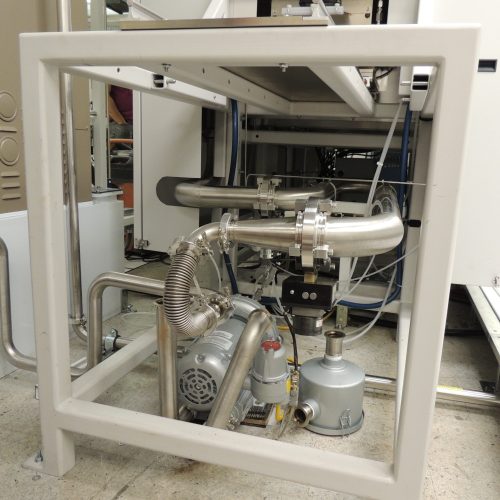

Orbital welding automates the welding process by rotating the welding electrode around a stationary workpiece, ensuring consistent and precise welds, often used in industries requiring high-quality and repeatable results.

Orbital welding is a specialized welding technique designed for precision and consistency in joining pipes and tubes. In this process, the welding electrode rotates mechanically around a stationary workpiece, ensuring uniformity and repeatability in weld quality. Orbital welding offers several advantages, including the ability to produce high-quality welds in critical applications such as aerospace, semiconductor manufacturing, and pharmaceutical production. By automating the welding process and controlling parameters such as arc voltage, travel speed, and rotation, orbital welding minimizes human error and ensures consistent weld penetration and fusion. This results in welds with superior strength, integrity, and reliability, making orbital welding an indispensable tool for industries that demand the highest standards of quality and performance.